PVDF Biogas Storage Holder for Combined Heat and Power Project

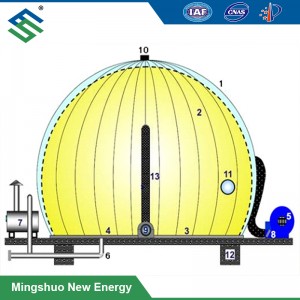

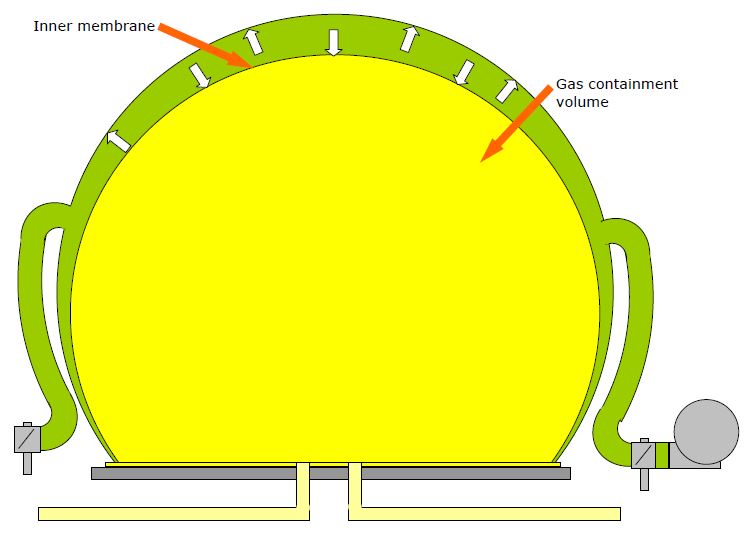

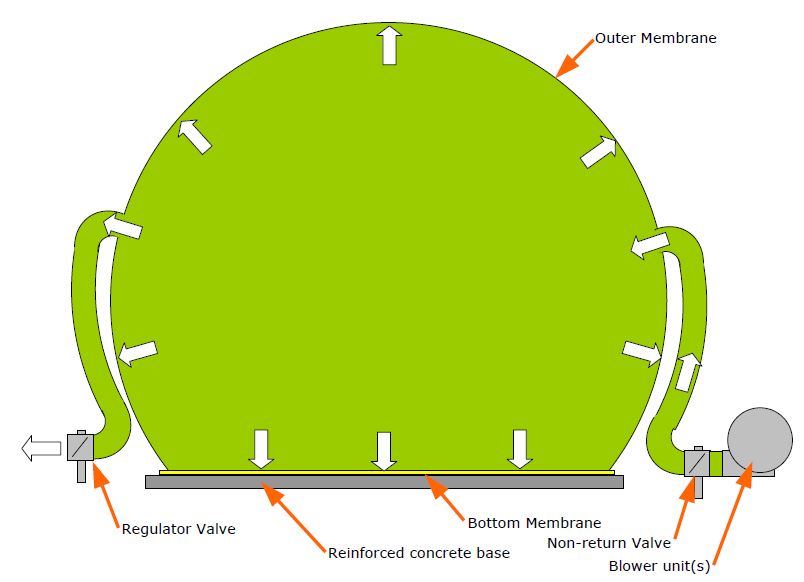

Mingshuo double membrane gas storage system is mainly formed by inner membrane, outer membrane, bottom membrane, pressure control unit, safety seal and other auxiliary equipments. This double membrane gas storage tank designed and manufactured by our company can apply to biogas engineering as well as petroleum gas storage. The inner membrane is used for gas storage while the outer membrane keeps the air pressure constant. It has multiple advantages as the followings: low cost, long lifespan, simple installtion, simple operation, fully automatic control, freely maintenance and so on. It is also a substitute product of traditional colossal steel tank in gas storage. We can provide technical research, customized products, installation instruction and other services according to your requirements. We adopt Germany advanced technology and devote ourselves to providing safe and reliable gas holder for our customers.

Mingshuo Double Membrane Gas Holder is a durable air supported structure specifically designed for the purpose of biogas storage. Typically, the Gas Holder is installed as part of the anaerobic digestion system in a wastewater treatment plant, agricultural digestion schemes, landfill sites and combined heat-and-power plants that use digested organic materials to generate biogas as an energy source.

Typical Installation:

The gasholder is installed between the digester and the gas consumption equipment:

Application: Storage of multiple neutral gas such as biogas, air, carbon dioxide, oxygen and so on.

Membrane Specifications:

Biogas specialized membrane material is made of high strengthened, high elastic synthetic engineering membrane with perfect anti acid and anti corrosion ability, so we do not have to do regular maintenance when using double membrane biogas tank. The biogas specific membrane has been widely used in energy treatment, sewage treatment, agriculture waste treatment, landfill site and other industries. The lifespan is more than 20 years.

|

Type |

Weight (g/m2) |

Thickness (mm) |

Tensile strength (N/5cm) |

Fire-protection standard |

Suitable temperature (°C) |

|

Inner membrane |

800-1500 |

0.8-1.5 |

3000-7000 |

DIN4102 B1 |

-30 ~ 70 |

|

Outer membrane |

800-4500 |

0.8-1.5 |

3000-7000 |

DIN4102 B1 |

-30 ~ 70 |

|

Bottom membrane |

800-1500 |

0.8-1.5 |

3000-7000 |

DIN4102 B1 |

-30 ~ 70 |

Product Parameter:

Material: PVDF

Fire protection level: B1

Tensile strength: 3000-7000N/5cm

Gas storage capacity: 50m3 to 5000m3

Inner membrane working pressure: 2000Pa

Outer membrane working pressure: 300-800Pa

Working temperature: -40ºC to 70ºC

Storage volumes can be designed to suit the process production and consumption requirements. Smaller units may be required as a buffer storage on a continuously operated plant, but larger gas storage units may be specified to hold the gas for use during the local peak-power requirement period, when energy produced can be sold on at a better price.

Performance and Characteristics:

Long service life

Maintenance free

Permanently gas-tight

Quickly installed

High operational reliability

Suitable for heavy wind and snow loads

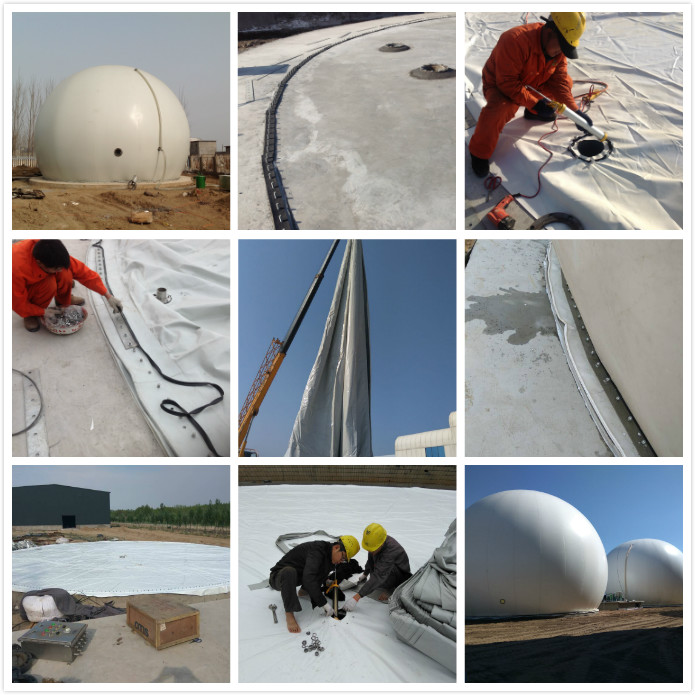

Project Display: COFCO CHP Project

Packaging and Installation:

Management System Certification: ISO9001:2008, IOS14001:2004, OHSAS18001:2007

With a registered capital of CNY 88 million, Mingshuo Environment Technology Group Co., Ltd. is founded in 2004. It is a high-tech enterprise dedicated to purifying sulfur-containing gases and realizing high-value utilization of organic wastes.

Adhering to the corporate spirit of integrity, innovation and mutual benefit, Mingshuo has gradually developed into a high-tech enterprise integrating R&D, consulting, design, manufacturing, construction and operation. It can provide comprehensive and sustainable ”one-stop” environmental services and overall solutions. The Group has passed ISO quality control, environmental management, occupational health and safety management system certifications, has professional construction qualifications for environmental engineering, D type pressure vessel manufacturing qualifications. It is also “Weifang Enterprise Technology Center”, “Weifang City Desulfurization and Denitrification Engineering Laboratory”, “Weifang City Biogas Equipment Engineering Technology Research Center”. The products have won the honorary titles of “China Green Products” and “China Famous Brand”. The chairman of the Group won the honorary title of “Shandong Province Circular Economy Person of the Year”.

Mingshuo’s products are divided into three series: desulfurizer and desulfurization equipment, biogas equipment, titanium, nickel and the like pressure vessel equipment. The desulfurizer and desulfurization equipment are mainly used for the treatment of biogas, natural gas, oilfield associated gas, shale gas, and other sulfur-containing gases for users in the fertilizer, coking, steel plant, and petroleum refining industries. The biogas equipment is mainly used for the treatment of organic waste such as livestock and poultry manure, kitchen waste, organic waste, straw and sewage. It realizes high-value utilization and turns waste into treasure. Titanium, nickel and the like pressure vessel is mainly used in oil refining, pharmaceutical, fertilizer, desalination, chemical and other industries. The Group has long-term cooperation with large domestic enterprises such as CNPC, Sinopec, COFCO, CSSC, Energy China, Beijing Drainage Group, INFORE ENVIRO, China Huadian Corporation Ltd., and Weichai Group. The Group has independent import and export rights, and has provided complete system services for lots of customers in the United States, Japan, Malaysia, the Philippines and other countries along the Belt and Road.

Mingshuo Environmental Group is committed to the development of environmental undertakings, always adhering to the development concept of “Cherish the Limited, and Create the Infinite”, and wish to go hand in hand with you to create a better future!